CD 32 dosing machine for biscuits and pastry products

Description

The CD 32 dosing machine is an automatic dosing machine for pastry shops with a hopper capacity of 32 liters. Designed to be versatile and easy to handle for a simple semi-dense pour that will allow you to produce different types of cast biscuits and confectionery products such as muffins, sponge cake, marzipan, cupcake, "brutti ma buoni", meringues, ladyfingers, plumcakes, medalas, etc. The CD 32 pouring machine is computerized and built to meet the multiple processing needs of confectioners regarding the automatic dosing and shaping of any type of dough, with the possibility of configuring up to 400 recipes. Thanks to the numerous accessories available, this biscuit machine adapts to the most varied needs of the pastry chef. Thanks to the motorized extrusion heads it is possible to create curved castings such as donuts and crescents by customizing the rotation and speed parameters according to the shape you want to obtain. On request, the machine can be equipped with a device for cutting the biscuit flush: in this way it is possible to pass the dough through a mold of the desired shape and then cut it to maintain the shape of the biscuit. For liquid or semi-liquid doughs, thanks to the pump head technology, it will be possible to make products such as macarons, cupcakes, éclair and much more. The structure is in stainless steel and anticorodal aluminum, and the machine is equipped with a color touch screen control panel.

ACCESSORIES INCLUDED:

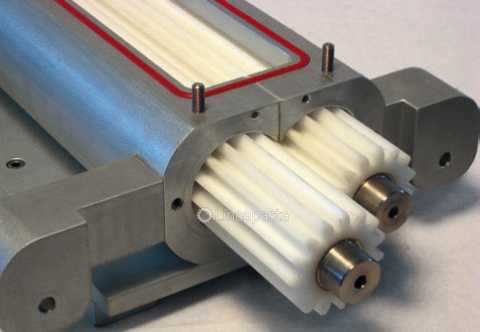

Rotating nozzle plate transmissions complete with:

- Electronic nozzle speed control

- 1 rotating nozzle plate with 6 outlets

- 6 straight smooth nozzles Ø10mm (plastic)

- 6 nozzles with straight teeth Ø10mm (plastic)

- 6 smooth decentralized nozzles outlet. Radius 16 mm / Ø10mm (bronze)

- Output 06 decentralized toothed nozzles. Radius 16 mm / Ø10mm (bronze)

Wire transmission complete with:

- 1 wire arch for mold with 6 outlets

- 1 wire mold, standard shape with 6 outlets

OPTIONAL ACCESSORIES:

- Pump head with roller set and hopper

- Standard roller head with roller set and hopper

- Mold for sponge cake and macaron

- Rotating nozzle with customized number of outlets

- Filling block with customized number of outlets

- Fixed nozzle with customized number of outlets

- Flush cut molds with or without central hole

- Arc wire cut

TECHNICAL DATA:

- PLC complete with 400 memories

- Standard roller head complete with hopper (32 lt)

- Electronic regulation of the speed of the dosing rollers

- Electronically controlled bidirectional tray direction

- Electronic table height adjustment

- Lowering the height of the table during deposition to produce cone and multilayer biscuits

- Automatic tray detachment

- Automatic tray start function complete with counter

- Maximum passage of the tray under the nozzles 90 mm

- Maximum tray passage for special executions (to be evaluated) 140 mm

- Trays mm 400 x 600 x 20h (USA pots 18 x 26 inches)

- Voltage: 380V/50Hz 3Ph - 220V/60Hz 3Ph

- Machine dimensions: cm 126x 111x149h

- Machine weight: 300 kg

- Installed power: 2.7 kW

€ 0,00

The product has been added to the cart

Ask for information

Ask for information

Spain

Spain

Vietnam

Vietnam

USA

USA

Germany

Germany

Greece

Greece

Croatia

Croatia

Italy

Italy