Machine for biscuits cookies and bars MBS 250DV

Description

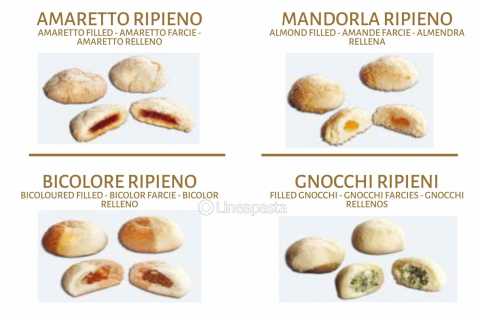

The MBS 250DV is not only a machine for single-color, two-color and three-color biscuits (cookies, in USA) and bars, but it is above all a screw extruder for sweet and savory products, filled or not, ideal for the production of bars and biscuits and also for any other type of gastronomic product with a round, spherical, cylindrical shape, with a granular structure up to 1 cm in diameter. It is a double vat machine with a capacity of 250 kg/h per vat, ideal for laboratories, gastronomies and catering companies who wish to have a machine with high potential at reduced dimensions, and who want a continuous production of different types of products ranging from sweet to savory using only one machine. With the addition of the "third vat" accessory it is possible to produce three-color or two-color formats with filling. The "third vat" accessory by means of a lobe system allows an accurate calibration of the quantity of creamy filling such as nutella, cream, jam and melted cheeses. In both vats the extrusion is fed by two mixing shafts that press the mixture against the extrusion screws to make the extrusion speed as homogeneous as possible. This double shaft system allows continuous production without having to stop the machine to fill the vats. The MBS 250DV is ideal for producing continuously bars, filled round biscuits such as Grisbi, cookies, Maamoul, Kibbeh, as well as savory products such as rice arancini, gnocchi, stuffed gnocchi, meatballs, canederli, etc. With this machine it is possible to produce bars of different shapes such as energy bars and crackers that with the MBS 250DV can be cut automatically by means of an automatic guillotine cutting system. Furthermore, it is possible to produce rolled biscuits, biscuits printed with a personalized mold and fillings in sight in a customizable shape. Thanks to the rollers to be positioned on the conveyor belt, it is possible to further customize the product with surface decorations. You can optionally decorate the biscuits with streaks of jam or other coverings. Finally, with accessories on request, it will be possible to obtain a perfect spherical shape with an automatic rounder, and decorate the surface of the product with sugar or pralines using a duster accessory. The production can also be further automated thanks to conveyor belts with retractable automatic deposit that will fill the trays in an automatic and orderly manner so as to be ready to be inserted into the oven. The wide versatility of this machine allows it to adapt perfectly to production needs by creating one or more products tailored to the customer who determines the dimensions and characteristics of the product. The MBS 250DV biscuit maker is equipped with variable value extrusion device, variable speed filling injection device to set the desired amount of filling, timed diaphragm cutting device and guillotine cutting device. It is built entirely in certified AISI 304 stainless steel and all parts in contact with the product are easily removable for effective washing even in the dishwasher. Finally, the machine complies with the directives of the European CE standard.

Upon request it is available the version MBS 250, with single vat.

TECHNICAL FEATURES:

Available settings:

- Amount of dough

- Amount of filling or second color

- Quantity according to filling

- Cutting length

- Cutting speed

- Speed of the unloading belt

- Recipe setting

- Saving recipes (on touch mod.)

- Automatic unloading of the product on the plate with coupling of the automatic deposit unit

OPTIONAL ACCESSORIES:

- Single vat version, MBS 250

- Mechanical diaphragm cutting knife

- Guillotine cutting unit with cutting of the ends of the product open/closed/knurled/thread cutting

- Product surface decoration unit with smooth, straight, inclined or rhomboidal roller

- Hot product surface molding unit

- Second filling injection unit for two-color product with filling

- Rotary extrusion head for "roller" and "twist" product

- Wire cutting unit

- Automatic deposit unit on plate - plate size 600 x 400/800/1000 mm

PRODUCTS THAT CAN BE REALIZED:

Some examples:

By means of a guillotine cutting device:

- Rectangular biscuits (rectangular cookies, in USA)

- Bars

- Crackers

- Breadsticks

By means of a diaphragm cutting device:

- Single color biscuits (single color cookies, in USA)

- Bi-color biscuits (bi-color cookies, in USA)

- Rolled biscuits (rolled cookies, in USA)

By means of a guillotine cutting device and "third vat" accessory:

- Stuffed crackers

- Stuffed breadsticks

By means of a diaphragm cutting device and "third vat" accessory:

- Two-colored biscuits with filling (two-colored cookies with filling, in USA)

- Stuffed canederli

- Rice arancini

- Stuffed gnocchi

TECHNICAL DATA:

- Dough extrusion group: double screw

- Filled extrusion group: double screw

- Stuffing injection by lobe pump

- Molding head: TS8 with two/three outlets

- Mechanical cutting unit: prod. 180/270 pieces/minute

- Product output conveyor belt: 300 mm adjustable

- Maximum size of product outlet: 32/50 mm

- Kneading/filling tanks capacity: 30 kg

- Maximum production: 10800/16200 pieces/hour

- Electro-pneumatic drive: 380V/50Hz 3Ph - 220V/60Hz 3Ph

- Electric absorption: 8 kW

€ 0,00

The product has been added to the cart

Ask for information

Ask for information

Spain

Spain

Vietnam

Vietnam

USA

USA

Germany

Germany

Greece

Greece

Croatia

Croatia

Italy

Italy