Important: this object is no longer available because already sold or not for sale anymore. We invite you to visit our website to find any similar equipment.

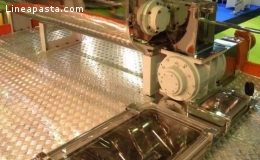

Short cut pasta line 3000 Kg/h

Description

New short cut pasta lines that can produce up to 3000 Kg of short cut pasta per hour.

Semolina or wheat flour Cyclone tank – made of stainless steel 304;

Agitator – complete with paddle for turning product, made of stainless steel; 2 min./max. capacity level probes.

Support structure:

- Semolina Feeding Unit: stainless steel structure and controlled by inverter, working automatically with different values for different kind of pasta and macaroni types, for this supported by PLC system and controlled SCADA system.

- Water Feeding Unit:

Flow Meter : Badger Meter (Germany)

Water pump is Alem Bertola (Turkey) with accuracy +/- % 0,25

- Control Valve : Samson Electromagnetic control valve

- Speed Mixer: stainless steel structure, pallets and screw.

- Main Mixer: stainless steel structure and pallet. Special design load reducer gear box system. Double shaft working pallets.

- Vacuum Lock

- Vacuum Mixer

Die’s diameter 670 mm

- Shaking Pre-Dryer: 3 layers shaking system. Working with 5 pcs aluminum angular axial fans.

- Shaped Bucket Elevator: 1 pc elevators from trabatto to dryer. Bucket lengths are 670 mm. Plastic buckets.

- Combined Dryer: all structure is stainless Steel, 11 layers , 13 section, special perforated aluminum conveyor belts which covered with stainless wire, vibro lay out, all values of temperature and speed is electronically controlled by PLC and water valves have percentage variation with 3 way pneumatic valves (Samson) controlled by Scada control system.

Structure is placed on elevated prop 250 mm for defending construction from oxidizing. There is 32 pcs drying fans on it their control units and air exhaust and fresh air pumps. With air ventilation system with it’s PLC electronic system. Inside the dryer valves are Bellow Sealed Globe Valves as PN16 with Turkish Made. Computerized water control by 3 way SAMSON control valves.

All the covers and their isolation on dryer is made by Stainless Steel as 304 and PU isolated covers. They can be open from top side and locked safely. Side covers are 63 mm thickness and well isolated.

- Pasta loading distributor – equipped with vibratory tier driven by 2 vibratory motors – the tier is made of stainless steel, heated by means of coils positioned underneath the vibratory tier with pre-heated inlet.

- Cooler Unit; Moving with band system, cooling with air circulation and the air which passed from cold water serpentines by axial fans as one layer. Length: 450 cm, Width: 200 cm, Height : 300 cm

- Die: 1 pc die will be given with the line, shape will be selected by the client.

Installed Motor Power Of Line 200 KW

Absorbed Electricity Power 170 KW / HOUR (avarage)

Installed Power for Dryer : 110°C - 130°C with 950.000 Kcal/Hour

Absorbed Power for Dryer 110°C - 130°C with 750.000 Kcal/Hour

Needed Cooled Water : 7°C with 120.000 Kcal/Hour

Needed Boiler capacity : 110°C - 130°C with 1.150.000 Kcal/Hour

24 Months Electrical and Mechanical Guarantee.

INCLUDED MATERIALS IN THE OFFER:

1- Raw material feeding with Air Transfer, blower and 20 Tons Silo on the Rotoflow

2- Press

3- Shaker pre-dryer(trabatto)

4- Elevator

5- Dryer with pneumatic thermal control center

6- Cooler

7- Electric Control Panel with cabelling and Scada System with Computer

8- Installation included

Enter the delivery address to calculate the shipping costs and proceed with the purchase

The product has been added to the cart

USA

USA

France

France

Australia

Australia

Spain

Spain

New Zealand

New Zealand

Italy

Italy

Germany

Germany